CP603 COPPER END FEED FITTING REDUCER

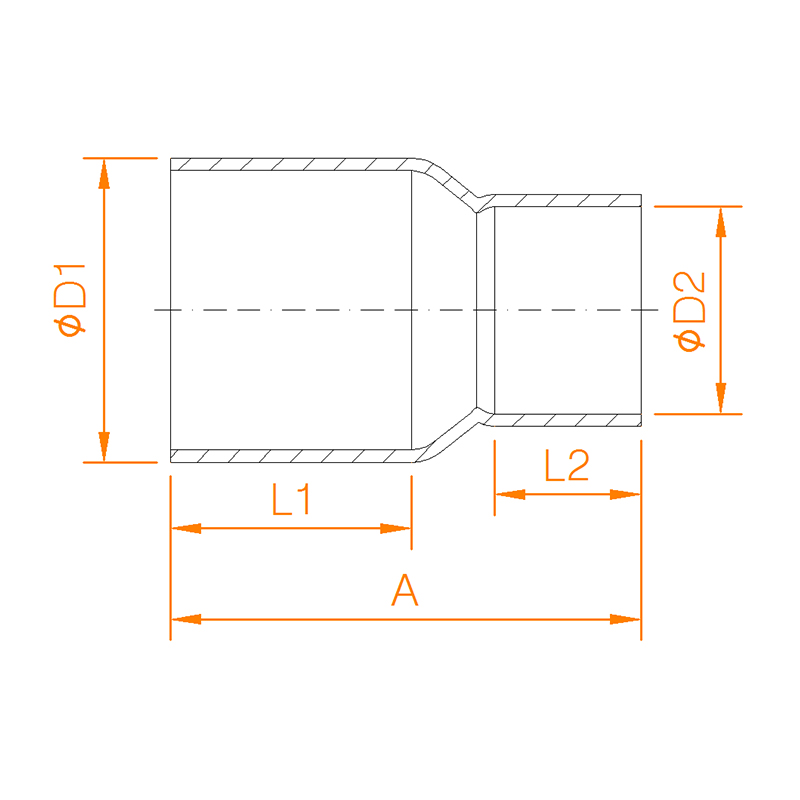

Model & Structure Dimension

| Model | Specification(mm) | D1 | D2 | L1 | L2 | A |

| CP603B0806 | 8×6 | 8 | 6 | 8.8 | 5.8 | 15 |

| CP603B1006 | 10×6 | 10 | 6 | 9.8 | 5.8 | 19 |

| CP603B1008 | 10×8 | 10 | 8 | 9.8 | 6.8 | 17.5 |

| CP603B1206 | 12×6 | 12 | 6 | 10.6 | 5.8 | 21 |

| CP603B1208 | 12×8 | 12 | 8 | 10.6 | 6.8 | 21.5 |

| CP603B1210 | 12×10 | 12 | 10 | 10.6 | 7.8 | 20 |

| CP603B1410 | 14×10 | 14 | 10 | 12.6 | 7.8 | 23 |

| CP603B1412 | 14×12 | 14 | 12 | 12.6 | 8.6 | 23 |

| CP603B1508 | 15×8 | 15 | 8 | 12.6 | 6.8 | 24.5 |

| CP603B1510 | 15×10 | 15 | 10 | 12.6 | 7.8 | 24.8 |

| CP603B1512 | 15×12 | 15 | 12 | 12.6 | 8.6 | 25 |

| CP603B1514 | 15×14 | 15 | 14 | 12.6 | 10.6 | 26 |

| CP603B1610 | 16×10 | 16 | 10 | 12.6 | 7.8 | 26 |

| CP603B1612 | 16×12 | 16 | 12 | 12.6 | 8.6 | 26 |

| CP603B1614 | 16×14 | 16 | 14 | 12.6 | 10.6 | 26 |

| CP603B1615 | 16×15 | 16 | 15 | 12.6 | 10.6 | 26 |

| CP603B1812 | 18×12 | 18 | 12 | 14.6 | 8.6 | 28 |

| CP603B1814 | 18×14 | 18 | 14 | 14.6 | 10.6 | 28 |

| CP603B1815 | 18×15 | 18 | 15 | 14.6 | 10.6 | 28 |

| CP603B1816 | 18×16 | 18 | 16 | 14.6 | 10.6 | 27.5 |

| CP603B2014 | 20×14 | 20 | 14 | 17.4 | 10.6 | 33 |

| CP603B2016 | 20×16 | 20 | 16 | 17.4 | 10.6 | 32 |

| CP603B2114 | 21×14.7 | 21 | 14.7 | 17.4 | 10.6 | 33 |

| CP603B2210 | 22×10 | 22 | 10 | 17.4 | 7.8 | 32.5 |

| CP603B2212 | 22×12 | 22 | 12 | 17.4 | 8.6 | 32.5 |

| CP603B2214 | 22×14 | 22 | 14 | 17.4 | 10.6 | 34 |

| CP603B2215 | 22×15 | 22 | 15 | 17.4 | 10.6 | 34 |

| CP603B2216 | 22×16 | 22 | 16 | 17.4 | 10.6 | 34 |

| CP603B2218 | 22×18 | 22 | 18 | 17.4 | 12.6 | 34 |

| CP603B2220 | 22×20 | 22 | 20 | 17.4 | 15.4 | 34 |

| CP603B2518 | 25×18 | 25 | 18 | 18.4 | 12.6 | 37.5 |

| CP603B2721 | 27.4×21 | 27.4 | 21 | 20.1 | 15.4 | 41 |

| CP603B2810 | 28×10 | 28 | 10 | 20.4 | 7.8 | 40.5 |

| CP603B2812 | 28×12 | 28 | 12 | 20.4 | 8.6 | 40.5 |

| CP603B2814 | 28×14 | 28 | 14 | 20.4 | 10.6 | 40.5 |

| CP603B2815 | 28×15 | 28 | 15 | 20.4 | 10.6 | 40 |

| CP603B2816 | 28×16 | 28 | 16 | 20.4 | 10.6 | 40 |

| CP603B2818 | 28×18 | 28 | 18 | 20.4 | 12.6 | 40.5 |

| CP603B2820 | 28×20 | 28 | 20 | 20.4 | 15.4 | 42 |

| CP603B2822 | 28×22 | 28 | 22 | 20.4 | 15.4 | 41 |

| CP603B3218 | 32×18 | 32 | 18 | 25 | 12.6 | 46 |

| CP603B3220 | 32×20 | 32 | 20 | 25 | 15.4 | 48 |

| CP603B3222 | 32×22 | 32 | 22 | 25 | 15.4 | 48 |

| CP603B3228 | 32×28 | 32 | 28 | 25 | 18.4 | 48.5 |

| CP603B3515 | 35×15 | 35 | 15 | 25 | 10.6 | 48.5 |

| CP603B3518 | 35×18 | 35 | 18 | 25 | 12.6 | 48.5 |

| CP603B3522 | 35×22 | 35 | 22 | 25 | 15.4 | 48.5 |

| CP603B3528 | 35×28 | 35 | 28 | 25 | 18.4 | 50 |

| CP603B3532 | 35×32 | 35 | 32 | 25 | 23 | 53 |

| CP603B3622 | 36×22 | 36 | 22 | 25 | 15.4 | 51 |

| CP603B3632 | 36×32 | 36 | 32 | 25 | 23 | 53 |

| CP603B3635 | 36×35 | 36 | 35 | 25 | 23 | 52 |

| CP603B4022 | 40×22 | 40 | 22 | 29 | 15.4 | 56.5 |

| CP603B4028 | 40×28 | 40 | 28 | 29 | 18.4 | 56.5 |

| CP603B4032 | 40×32 | 40 | 32 | 29 | 23 | 58.5 |

| CP603B4035 | 40×35 | 40 | 35 | 29 | 23 | 57.5 |

| CP603B4036 | 40×36 | 40 | 36 | 29 | 23 | 57.5 |

| CP603B4027 | 40.5×27.4 | 40.5 | 27.4 | 29 | 18.4 | 57 |

| CP603B4215 | 42×15 | 42 | 15 | 29 | 10.6 | 54 |

| CP603B4218 | 42×18 | 42 | 18 | 29 | 12.6 | 56 |

| CP603B4222 | 42×22 | 42 | 22 | 29 | 15.4 | 57 |

| CP603B4228 | 42×28 | 42 | 28 | 29 | 18.4 | 57 |

| CP603B4232 | 42×32 | 42 | 32 | 29 | 23 | 60 |

| CP603B4235 | 42×35 | 42 | 35 | 29 | 23 | 60 |

| CP603B5228 | 52×28 | 52 | 28 | 34 | 18.4 | 68 |

| CP603B5232 | 52×32 | 52 | 32 | 34 | 23 | 69.5 |

| CP603B5236 | 52×36 | 52 | 36 | 34 | 23 | 68 |

| CP603B5240 | 52×40 | 52 | 40 | 34 | 27 | 70.5 |

| CP603B5242 | 52×42 | 52 | 42 | 34 | 27 | 69 |

| CP603B5340 | 53.6×40.5 | 53.6 | 40.5 | 34 | 27 | 70 |

| CP603B5415 | 54×15 | 54 | 15 | 34 | 10.6 | 63 |

| CP603B5418 | 54×18 | 54 | 18 | 34 | 12.6 | 63.5 |

| CP603B5422 | 54×22 | 54 | 22 | 34 | 15.4 | 65 |

| CP603B5428 | 54×28 | 54 | 28 | 34 | 18.4 | 68 |

| CP603B5432 | 54×32 | 54 | 32 | 34 | 23 | 72 |

| CP603B5435 | 54×35 | 54 | 35 | 34 | 23 | 71 |

| CP603B5440 | 54×40 | 54 | 40 | 34 | 27 | 71 |

| CP603B5442 | 54×42 | 54 | 42 | 34 | 27 | 70 |

| CP603B5452 | 54×52 | 54 | 52 | 34 | 32 | 72 |

Product Features

The copper solder ring fittings are WRAS approved.

All of our solder ring fittings come with lead-free solder to ISO 9453 embedded within them.

Solder ring fittings are quick and easy to install, just heat the ends with a blowtorch, the embedded solder will melt creating a watertight joint. These copper pipe fittings are ideal for potable (drinking) water as well as heating and chilled water in conjunction with BS EN 1057 copper pipe and tube.

Product Description

1. Use high quality copper, no harm to body, resistant to corrosion.

2. 16 bar pressure rated at up to 30°C with an operating temperature range of 0°C – 110°C.

3. Packed in inner bag. Label tag can be used individual for retail market.

Our Advantage

1. We accumulated rich experience through cooperation with many customers of different demands for more than 20 years.

2. In case any claim occurred, our product libility insurance can look after to eliminate the risk.

FAQ

1. Can I give a sample order?

A: Yes, we welcome sample order to test or check quality.

2. Is there any MOQ limit for our order?

A: Yes, most of the items have MOQ limit. We do accept small qty at the beginning of our cooperation so that you can check our products.

3. How to ship the goods and how long to deliver the goods?

A. Usually the goods shipped by sea. In general, the leading time is 25 days to 35 days.

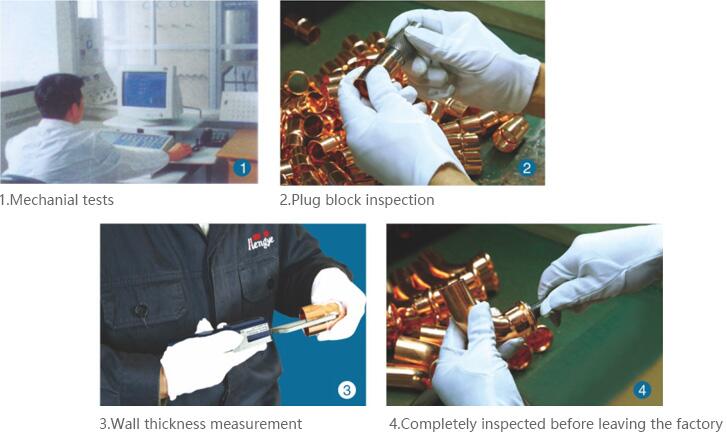

4. How to control the quality and what's the guarantee?

A. We buy goods only from reliable manufacturers, all carry out comprehensive quality inspection during every step of production procedure. We send our QC to inspect goods strictly and issue report to customer before shipment.

We arrange shipment after goods passed our inspection.

We offer certain period warranty to our products accordingly.

5. How to deal with the unqualified product?

A. If defective occurred occasionally, shipping sample or stock will be checked first.

Or we will test the unqualified product sample to find the root cause. Issue 4D report and give final solution.

6. Can you produce according to our design or sample?

A. Sure, we have our own professional R&D team to follow your requirement. OEM and ODM are both welcomed.